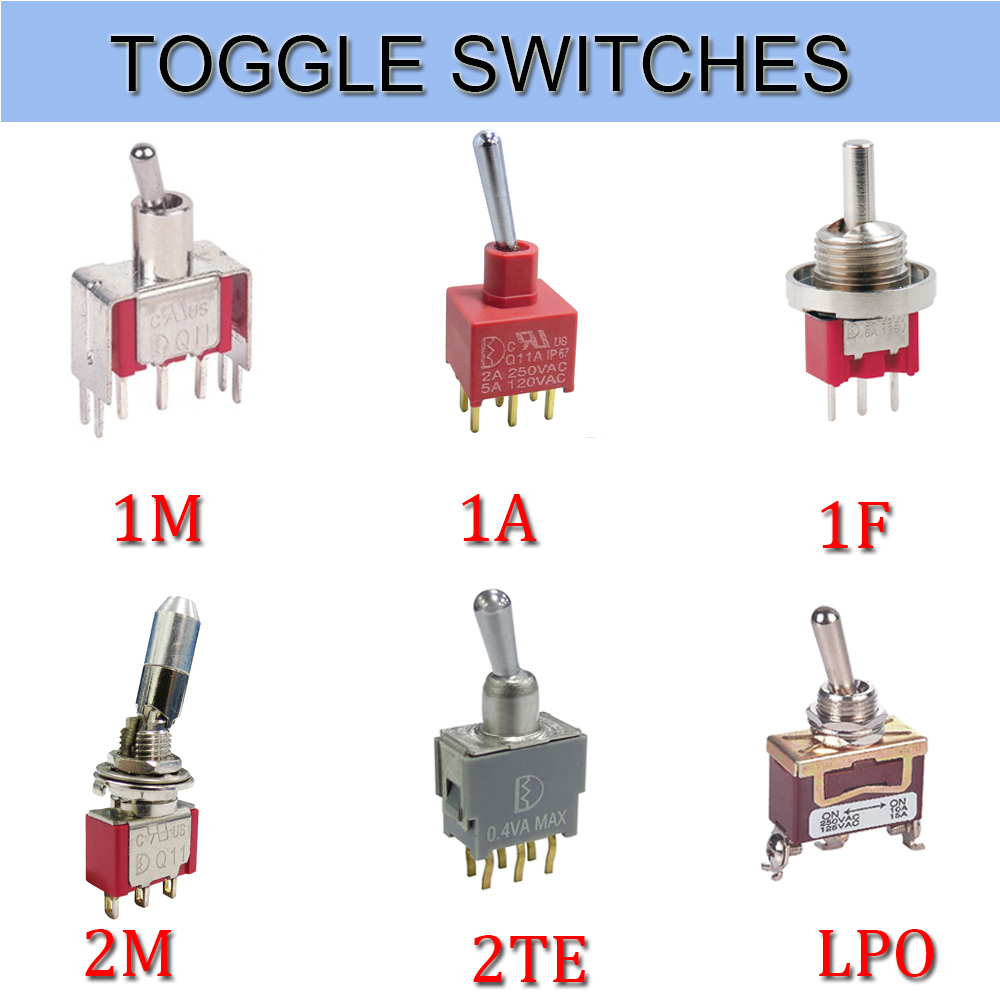

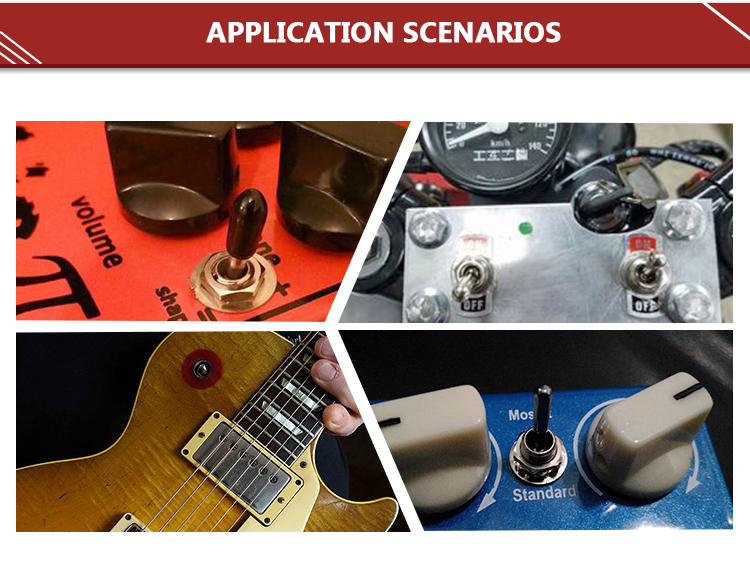

The flammability and severity of power cables during a fire are critical concerns, particularly in power plants and large substations, where a fire could disrupt other circuits. Ensuring the fire safety of power cables is essential for maintaining the normal operation of electrical systems. Power cables are vital components in electrical engineering, used to transmit and distribute electrical energy. Composed of an insulated core wire, an insulating sheath, and a protective layer, they are designed to operate under diverse environmental conditions with excellent insulation, waterproofing, and mechanical properties. However, overcurrents and overheating can compromise cable performance, potentially leading to fires. This discussion aims to explore the fire protection technologies applicable to power cables. 1. Creating an Optimal Operating Environment Cable trenches and tunnels should feature robust drainage systems, including shallow trenches and collection wells, ensuring efficient water removal. Automatic pumping systems can be installed if necessary to maintain dry conditions. The design should include a proper drainage gradient along the length of the tunnel. Efforts should be made to prevent water, corrosive gases, or flammable substances from infiltrating these areas. Natural ventilation is preferable, though mechanical ventilation can be combined with it when air temperatures exceed 40-50°C due to regular cable loads. Fans within the ventilation system should be linked to fire detectors to shut off automatically in case of a fire. Cable tunnels should not serve as air intakes for ventilation systems. Fire doors should remain open unless absolutely necessary and should not completely enclose cables. Gaps in cable trench covers should be sealed to prevent air circulation that could exacerbate fire spread. However, complete enclosure hinders routine inspections and timely identification of cable faults. Statistics indicate that roughly 70% of cable fires and explosions result from failures at the cable heads. Producing cable heads requires strict adherence to material and process standards to ensure their lifespan matches that of the cable itself. The voltage and insulation levels must meet or exceed those of the connected cables. Insulating mats on either side of the head must withstand voltages of at least twice the cable's protective layer. Joint designs should align with environmental conditions without impeding cable flow capacity. Fire-resistant tape should be applied within 2-3 meters on either side of the cable head for added protection. Overall, cable insulation weaknesses necessitate close monitoring of cable heads. Terminal heads should never be located in cable trenches or tunnels. Intermediate cable heads require registration and testing with various diagnostic tools. Early withdrawal should occur upon detecting abnormal temperature rises, odors, or smoke to prevent operational fires. Adequate spacing should exist between intermediate cable heads, and stringent sealing measures should connect cable heads to other cables. 2. Enhancing Preventive Testing Post-installation, power cables and accessories should undergo DC withstand voltage tests. Analyzing these data allows comparisons with similar cables or historical data to identify trends. Elevated leakage currents during DC tests could signal cable insulation defects and require careful analysis. Factors such as increasing voltage or prolonged pressurization, higher values than comparable cables, rising trends compared to previous measurements, or significant phase imbalances suggest potential issues. Adjustments to test parameters might be needed for accurate assessments. Standards for plastic-insulated power cables can be referenced in Chapter 17 of the "Installation Engineering Electrical Equipment Handling Test Standards" (GB50150-91), specifying a 4x rated voltage test for 15 minutes. 3. Strengthening Quality Control of Cable Head Production 4. Preventing Other Equipment from Igniting Cables Oil-filled electrical equipment, coal-handling systems, and gasoline engines pose ignition risks to cables. Sealing cable trench covers near such equipment is crucial to prevent oil leaks from igniting cables. Regular cleaning of dust near coal conveyors and mills prevents spontaneous combustion. Milling system explosion-proof doors should house cables within fireproof boxes to protect against accidental ignitions. 5. Utilizing Sealing, Blocking, Coating, and Wrapping Measures Fireproof coatings offer thin layers with minimal thermal impact yet effective fire resistance. However, issues like improper coating selection, counterfeit products, peeling, uneven thickness, and corners cut during application persist. Most cable projects rely on solvent-based coatings, which present challenges such as toxicity, cost, transport safety, and environmental concerns. Their cold, water, and oil resistance are subpar, and bending resistance is poor, limiting their use to exposed cables prone to cracking and peeling. Instead of relying heavily on coatings, sealing, blocking, and separation techniques should be prioritized. For instance, sealing methods should prevent a single cable from igniting multiple cables. Trenches, tunnels, trays, and jackets must be tightly sealed to avoid cascading fires. Firewalls and doors should be installed every 60 to 100 meters in trenches and tunnels, with layers in shafts and separation between power and control cables. Important pathways should feature automatic alarm and fire-extinguishing systems, such as water spray or mist devices, for early intervention. Fireproof seals must be tight and thick enough to withstand the number of cables involved. Damaged seals should be promptly repaired, and fire doors should auto-close during fires. Seals need mechanical strength to endure air pressure surges during electrical shorts. Common materials include fire-resistant rock wool, asbestos boards, ropes, clay, and advanced composites. Selection depends on specific project conditions and areas requiring protection. Anti-rat and snake-proofing facilities are also essential to prevent animal-related incidents. Additional considerations involve ensuring that fireproof materials like rock wool, asbestos, clay, and modern composites are properly applied across critical zones such as high and low-voltage switchgear rooms, distribution shafts, control rooms, trays, and walls crossing national boundaries. Perfecting these measures ensures long-term cable integrity and operational safety. Toggle switches Toggle switches, also called On Off Toggle Switches, is often used as the switching device of the equipment stalls. Meanwhile, we are also offer our customers Key Switches, Metal Switches, Automotive Switches, Push Button Switches, etc. The Electrical Toggle Switches is a manually controlled Toggle Switches similar to the dial switch. Most of this Latching Toggle Switches are widely used in on-off control of AC and DC power circuits, and are less commonly used in circuits of several kilohertz or up to 1 megahertz. Let's take a look at the following. 1. Splash-proof knob button switch The panel is installed with a splash-proof `O` ring seal, and the knob is a ball. It is a splash-proof ball button knob switch. Its terminals are in a straight line and the bottom of the terminals is sealed with epoxy resin. Strong corrosion resistance, suitable for automotive parts 2. Vertical Mount Right Angle Toggle Switch The vertical mounting of the terminals and the terminal pins are right-angled, so it is a vertically mounted right-angled toggle switch. Its contacts are gold-plated and highly reliable. Mostly used in anti-theft devices, alert system. 3. Bipolar single toggle switch At the same time, the switch breaks the phase line and the N line and controls one branch. Therefore, it is a bipolar single toggle switches. The contacts are in 3PDT form and are used for multimedia speakers and stereos. 4. Standard surface mount unthreaded toggle switches The terminal adopts the standard mounting mode. Its sleeve has no thread. It is called a standard surface mount screw-less switch. The contacts are SPDT and its electrical life is as high as 55,000. Used for medical equipment 5. Horizontally mounted right-angle toggle switch Compared to the vertical switch, it only changes direction to horizontal, so it is horizontally mounted right-angle toggle switch. The contacts are double-pole double-throw and the bottom of the terminal is Epoxy Seal. Mostly used for computer peripherals. Toggle Switches,Toggle Switch On Off,ON-ON Toggle Switch,HT802 Series Toggle switches,Momentary Toggle Switch,High Current Toggle Switch,Waterproof Toggle Switch,Toggle Switches (ON)-OFF,IP68 Toggle Switch YESWITCH ELECTRONICS CO., LTD. , https://www.yeswitches.com